Tesla 3

By Bill McCarthy

THERE is little doubt that Tesla has captured the imagination of the electric vehicle market as they become more and more common on UK roads. Conceived in Silicon Valley, after a slow start, the brand is now a runaway success.

The vehicles have incredible range, particularly with the twin motor model, minimalist, although high-end executive interior, and in its most sporty form, supercar challenging performance.

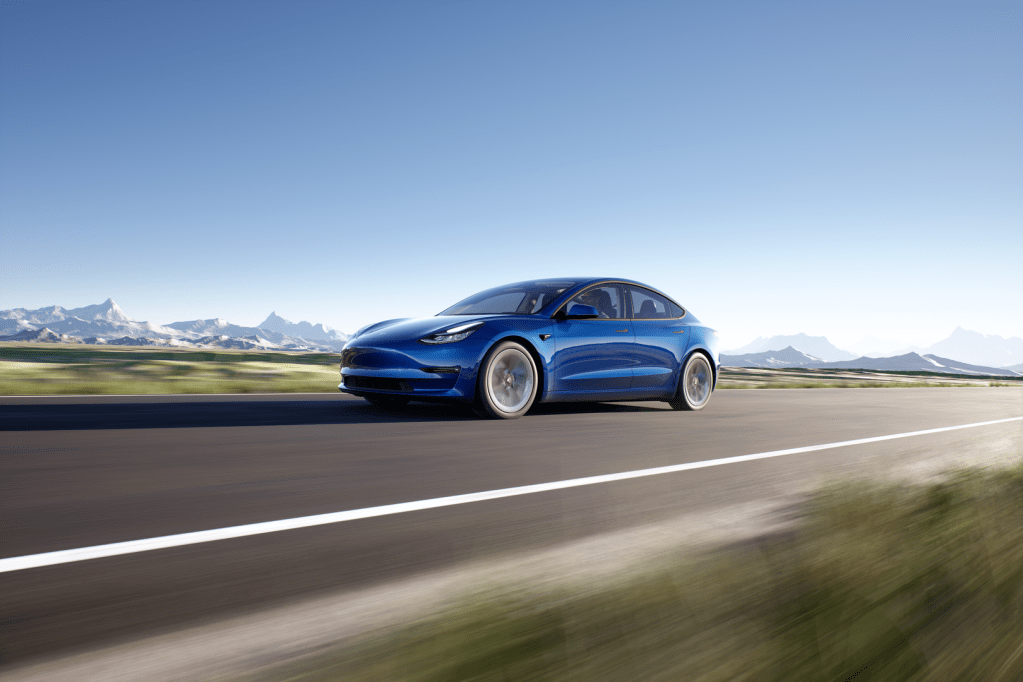

Designed as a mass market electric saloon, that’s exactly what it looks like. That is not to say it looks drab or mundane. It has sharp, coupe-like styling with only the rear spoiler hinting at the performance, while the 18-inch Aero wheels are striking and distinctive.

The range starts with the three specification Model 3, which at just over £40k for an executive, fully electric car, is a competitive price.

That has a claimed range of 278 miles, while this mid-range model driven here features a second electric motor, which boosts the mileage to well over 350 miles and adds the versatility of all wheel drive. The interior, particularly in this trim, is light and airy, much assisted by a full length panoramic roof.

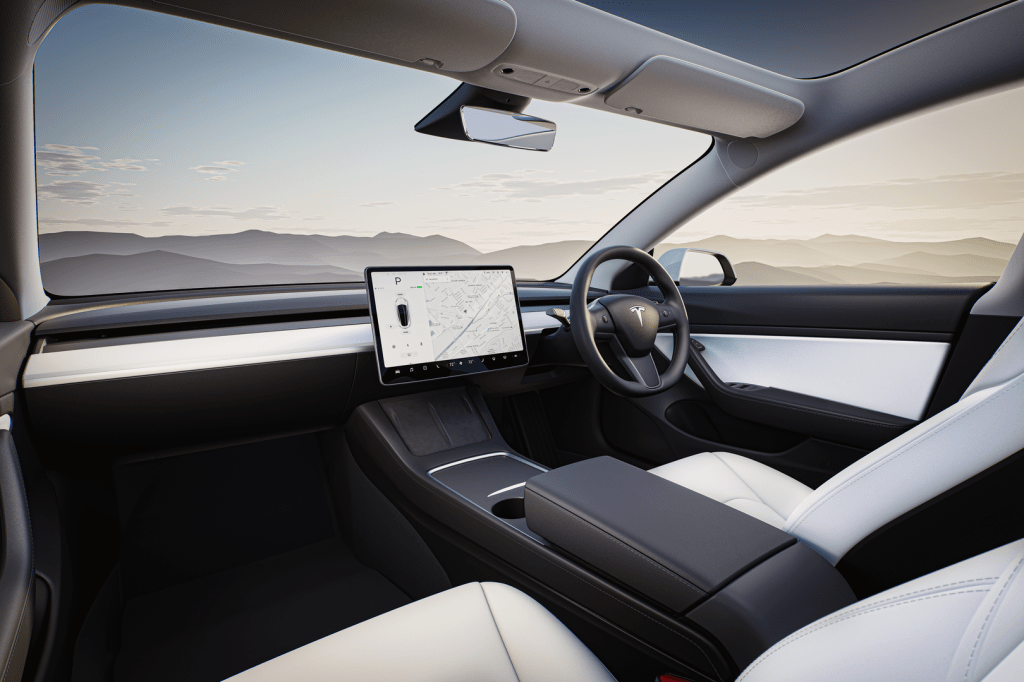

Capable of seating four people in comfort, it is finished in high quality trim and soft touch luxury. This model featured the optional Black and White Premium interior, a mixture of piano black and sumptuous white leather, which will set you back more than a grand.

The most revolutionary innovation is the brains of the car, a 15-inch tablet. It sits in the centre of a slimline dash, and controls virtually every function. It may not be to everyone’s taste, but the lack of other traditional controls adds to the minimalist look

There are a couple of steering wheel controls, an indicator stalk and a transmission selector stalk. No binnacle with dials, just for the most part, the touchscreen. This controls sat nav, connectivity, headlights, mirrors, wipers, steering wheel position and cruise control, you can even open the boot from there. In true tablet style it also includes a number of games to keep you occupied, maybe while waiting for it to charge at a charging station.

Recent upgrades also include phone charging mats, plus extra USB ports. The cars also regularly receive over-the-air software updates that add new features, increased performance and enhance existing functionality via Wi-Fi. It has recently received more than 20 software releases and more than 70 new features or improvements.

But the tablet tells the driver everything they need to know, although constantly glancing at the tablet to check speed and range can be distracting.

On the road, the Tesla is a bit of a wolf in sheep’s clothing. It may not look like a hot performer, but in true electric car style, acceleration is instant and exhilarating. This model hits 60mph in just over four seconds and it doesn’t run out of puff after the initial burst, accelerating up to 145 mph where permitted.

The 50-50 weight distribution of the battery, which runs the length of the floor pan, and the two electric motors, front and rear, means it his highly stable delivering the kind of handling you would expect from near supercar performance, while delivering a firm but comfortable ride for the occupants.

It may be an executive saloon, but it is still practical with effectively two boots, the one to rear is the largest and what would have been the engine compartment serves as a second space to provide a total of 542 litres. The absence of transmission tunnel and other combustion engine spaces, means oddment bins and are deep and plentiful.

It makes sense, obviously, to install a charger at home, while the range means top ups are more likely once a week rather than overnight every night.

Tesla superchargers allow drivers to charge in around half an hour while on longer journeys throughout the UK. They can now also be charged from other 7kW charging points at places like superstores.

Teslas are packed with safety features. The structure is a combination of aluminium and steel, for maximum strength while airbags and assisted braking and stability are mated with Basic Autopilot. Thus comes as standard and enables your car to steer, accelerate and brake automatically for other vehicles and pedestrians within its lane.

Factfile

Tesla Model 3 Long Range

Price: £47,500

Mechanical: 351bhp, 258 kW, dual electric motors driving all wheels via single speed manual transmission

Max Speed: 145mph

0-62mph: 4.2 seconds

Combined range: 360 miles

Insurance Group: 50

C02 emissions: 0g/km

Warranty: 4yrs/50,000 miles